- September 4, 2025

- Posted by: baldwin

- Category: Uncategorized

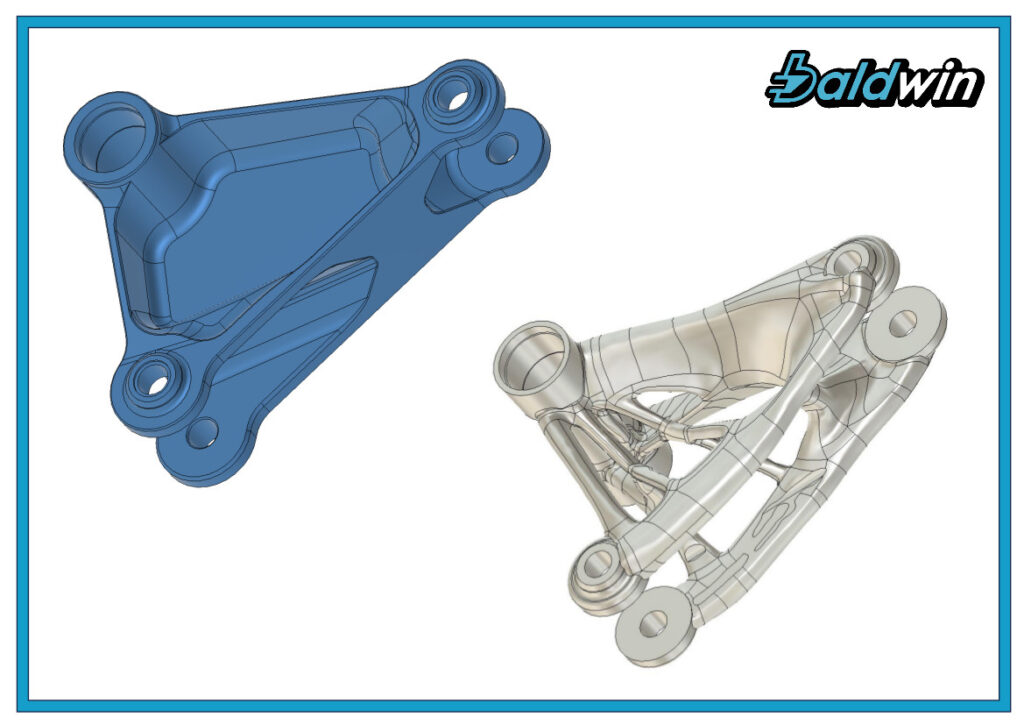

A linkage rocker is a nice part to optimize with regenerative design as the loads are well known. What I have learned so far from regenerative design is that:

✅ The optimized result didn’t look as what I thought was needed for highest stiffness, so we have found an interesting new design.

✅ The output model saved 30 grams or 10% of mass on a part that was already optimized by multiple loops of manual adjustment and FEM calculation.

✅ The output result has higher stiffness and lower stress than the original, so regenerative design works.

❌ Many times topology optimization returns a mesh model from which you can make a solid. Not ideal when you need smooth, machinable surfaces.

❌ There is not much room for other loads during handling or from misalignment. To increase the strength and stiffness in other directions than the main loads,

load cases need to be added. Making the design yourself, you would add this by feel.

Topology optimization is ideal for structural parts that have well-known loads on them.

Don’t expect the computer to make a superfast design for you, however, you can make a better design with similar total effort.

And you still need to know what you are doing 😊. With the right tools and experience, you can turn the output into a functional design.

Please post in the comments if you would like to receive the 3D step file outcome to have a look at this example.

Suspension, Lightweight, Machine building, Mechanical engineering, Regenerative design, Engineering, FEM, CAD, Maschinenbau

-Boudewijn

📞+31631378198